|

PSU REPLACEMENT - FAN

- ON HP Z3100 and Z3200 Printers

Notes on Tools, Materials, and Procedures by Mark Lindquist

Power Supply Unit Fan Replacement

HP DesignJet Z3100 - Z3200

Mark Lindquist 12/10/2014 - updated --1-10-2017

Fan replacement on

the HP DesignJet Z3100 - Z3200 PRINTER

By Mark Lindquist |

August-December 2014-1/5/2017

© 2017 Lindquist Studios All

Rights Reserved

PSU FAN Replacement Z3200 Printers

REPLACING THE HP Z3200 POWER SUPPLY UNIT (PSU) FAN

If you hear a loud noise coming from the left side of the printer as you

face it, and it seems to whine or squeal, and it continues to get worse

over time, it's probably the power supply fan. Amazing that such a small

thing can make so much noise!

For some reason HP determined that inexpensive parts were adequate for

this printer. A case in point is the power supply fan. When I took the

power supply apart to get at the fan I was really surprised to find that

it was essentially a $3.24 Computer fan with sleeve bearings. It is

unfathomable to me is that a fan that is required to run 24 seven 325

would be so cheap.

If you want to know the exact fan that is used in the HP Z3200ps 24”,

here it is:

The fan that was used in my HP Z3200 24" is a Sunon KD1208PTS1 13.GN 12V

DC

http://datasheet.octopart.com/KD1208PTS1.13.GN-Sunon-Fans-datasheet-9566827.pdf

Here is a photo of the old fan moments after it was removed (check out

the crud on it) you’ll see why blowing compressed air in there is just

not going to get it.

The crud gets caked on!

Ultimately, HP doesn’t have any information about replacing the Power

Supply Unit fan. It takes a ton of work and time to just replace the

fan, (because of having to take the power supply unit apart) so I’m sure

they only wanted their field technicians to replace the entire power

supply and be done with it, due to the cost of labor and difficulty of

tedious work in the field. There are companies who will trade you your

entire PSU for theirs, which has had a new fan put in and is

“refurbished”. The cost will be anywhere from $200 - $600. Google “HP

Z3100 Power Supply Unit Replacement” and you’ll find more than you want

to know.

In order to get at the fan it takes removing upwards of 40 screws from

the power supply unit and a lot of futzing around just to expose the

fan. Having actually pulled the power supply unit and opened it up and

replaced the fan with a quality fan I can say that it is quite a job but

not an unsurmountable one and with a little patience and perseverance it

is certainly doable.

The fan is essentially a simple computer case fan and you can find any

number of them online. If you want to take the easy way out, get an

entire PSU with who knows what fan they put in there and how, and send

yours off, never to be seen again. Just hope they sent you a “good one”

back! If you don’t want to get into replacing the fan yourself - take

the easy way out, send your PSU here.

I made the decision to replace my own fan so that I could clean the

circuit boards and inspect everything, plus I have an innate curiosity

about how things work. I figured I could take the power supply unit

apart, replace the fan and put it back together in an hour. Wrong. It

takes a couple to 3 hours, anyway, but I work slowly and carefully.

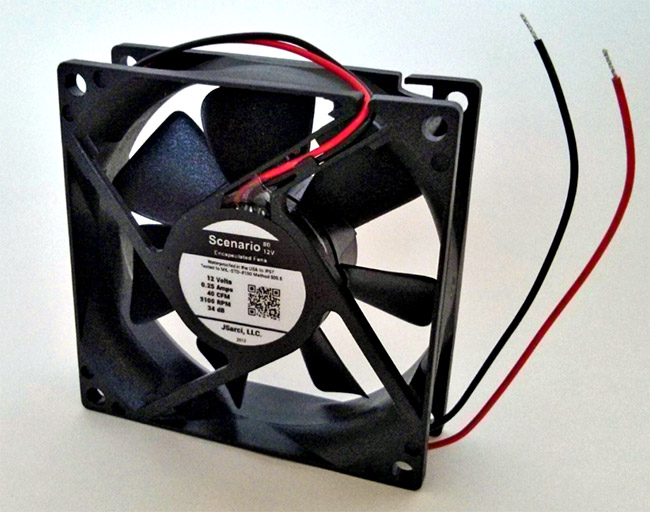

I got a waterproof fan because I figure they are made to withstand a lot

more climate issues. Just get one that has ball bearings instead of

sleeve bearings. I also got this fan because I knew I could easily

splice the wires into the plug and wires of the old, existing fan. It

was an easy fix - just nipped the old fan wires off about 5” past the

plug and soldered everything together and used heat shrink tubing and a

heat gun to go over the soldered areas.

Scenario80 12v - 80mm 12v BLDC Waterproof Fan IP57 - I got mine on

Amazon, but they don’t seem to be available there anymore.

NEW INFO on Replacement Fan - see below photo

NEW INFO ON

ALTERNATIVE FAN REPLACEMENT FROM PAUL BROOKS:

80mm fan alternative made by ADDA:

https://www.ebay.com/itm/80mm-25mm-Case-Fan-12V-67CFM-PC-CPU-Computer-Cooling-2-Wire-Ball-Brgs-8025-304-/181048018807?_trksid=p2385738.m4383.l4275.c10

80mm 25mm New Case Fan 12V 67CFM PC CPU Computer Cooling 2pin Ball Brgs

304*

This 80mm x 25mm 12V fan, part number AD0812UB-A73GP, has 2 ball

bearings for long life, a 3 pin/ 2 wire motherboard connector and 4 self

tapping screws.

The specifications include;

Voltage, 12V

Voltage Range, 6 to 13.8V

Current, 0.400Amps

Speed, 4500RPM at rated voltage and zero pressure

Flow (Max), 67CFM

Pressure Rise (Max), 0.30inH2O

Noise, 48dBA

THANKS PAUL!

Here is a very effective and simple video on how to take the PSU out,

once you have the printer cracked open:

Simple Screw Location Video

The existing fan is hidden deep in underneath in the back of the PSU. It

gets really dirty and is impossible to get at without taking the PSU off

the printer.

Be careful about taking a compressor hose to it to blow it out (DON’T) -

you’ll blow all that crud all over the electronics inside that are

unprotected.

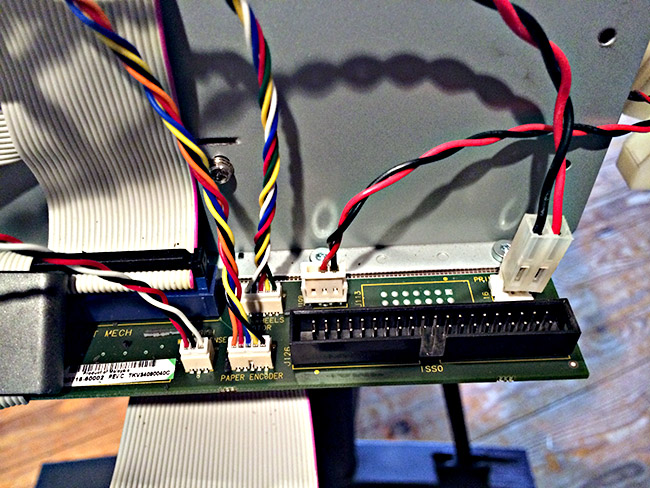

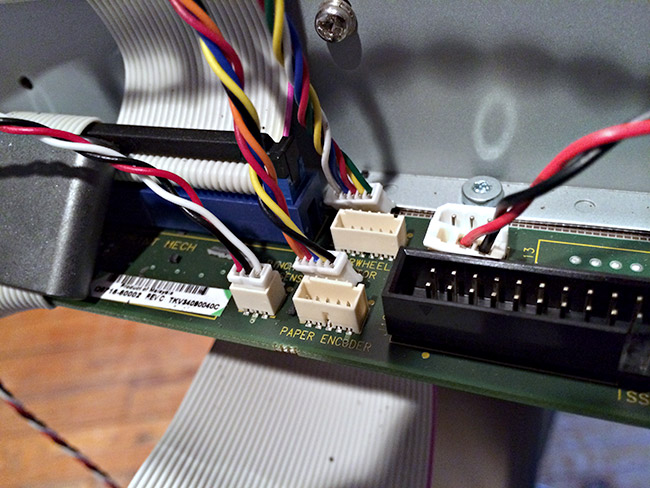

Before you remove any wires, from the PSU (Power Supply Unit), be sure

to take photos of where things go:

Take close-ups so you know where all the plugs go back in:

I even took closeups of the wires disconnected:

Once I got the PSU off the printer, and went after the screws, carefully

labeling them (photos help) since there are different types of screws, I

set up my soldering iron and tools to be able to work comfortably.

Additional Information:

Here is an excellent very short video about how to remove the specific

screws to release the PSU from the printer:

Designjet T Electronics Module - YouTube

A

short video on repairing the Power Supply

Unit by Les Sheppard: (Thanks Jim Mandraci for the link)

|

(These are my own

personal notes from repairs I have made.

I have made this web page for my own benefit, so I have a record of what

I have done.

If you use this information, do so at your own risk - I

assume no responsibility for errors.) |

|