|

REAR CARRIAGE BUSHING ON HP Z3100 and Z3200 Printers

Notes on Tools, Materials, and Procedures by Mark Lindquist

Rear Carriage Bushing Replacement

HP DesignJet Z3100 - Z3200

Mark Lindquist 12/10/2014 - updated --1-10-2017

Rear Carriage Bushing on

the HP DesignJet Z3100 - Z3200 PRINTER

By Mark Lindquist |

August-December 2014-1/5/2017

© 2017 Lindquist Studios All

Rights Reserved

HP Z3200 Rear Carriage Bushing

HP Z Series (Z3200) REAR CARRIAGE BUSHING REPLACEMENT

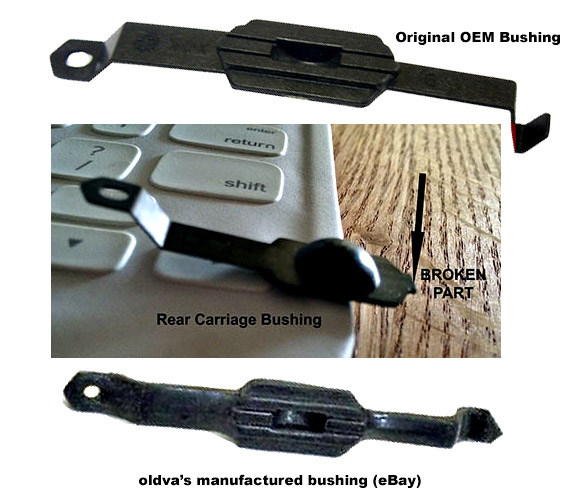

The rear carriage bushing (top in photo above), which is the flimsiest

of parts in the printer, is easily broken.

Thankfully, Bob Wert

of LPS, one of the most brilliant

repair guys on the face of the earth, has come up with a super quick and

easy fix for replacing the Rear Carriage Bushing. Bob is a

brilliant technician. See the video below. Thank you Bob!

I'm leaving everything below because

it's how repairing this part was done in the past, but really, skip all

of it and just do it the way Bob Wert shows in the video. While

you're at it - just buy the bushing from LPS.

(Notes in green from John Nollendorfs:)

"Nowhere is it well documented exactly where this bushing is located and

how it can be easily damaged. Before sliding the carriage off the end of

the rail, the bushing is located on top of the carriage, and needs to be

carefully depressed when sliding the carriage back in it's guide slot.

If you can be very careful sliding the carriage off the end of the

machine, you will notice the bushing, as you start to pull the carriage

off the rails. Start sliding the carriage very slowly, and observe the

bushing on top, as it slides out from under the rail."

Thanks for that tip John. These bushings are getting hard to find and

they are easy to break. They are also becoming pricey. Here is an

example:

Pricey Bushing

Rear Carriage Bushing replacement for HP Q5669-60687 on Z2100, Z3100,

Z3200

A replacement is available for about 15 bucks here

An enterprising guy on eBay with the user name of "oldva"actually

decided to manufacture a replacement that is beefier and much more

reliable (bottom in photo above). "...tough, abrasion and impact

resistant urethane and contains continuous strand carbon fiber tow

running the full length of the bushing."

I ordered the

bushing replacement from him and installed it and it works

perfectly. Sometimes he runs out on eBay.

From his listing:

“...Last year the 'rear carriage bushing' in my

Z2100 printer broke which allowed the print heads to scrape across the

media it was printing on. I was lucky in that the broken part fell on

the floor under the printer, so identification of the problem was easy

and I didn't have to go 'digging' into the printer to recover any broken

pieces that might jam things up. This 'bushing' is one of the components

that set the height of the print heads over the media. Without this

'bushing' in place the print heads may contact the media, especially if

printing on a thick media, such as canvas or board and leave drag marks

in the print path.

I searched and searched for a replacement part, but at the time none

were available, not even from HP ! It appears that this bushing is a

common failure point, as I have found numerous inquires on the internet

regarding it. So, "Desperation being the Mother of Invention" , I headed

down to our workshop, where we do have some equipment for molding

plastic parts. After noting the failure point of the old bushing, I

designed a mold for a new style bushing which would correct the

weaknesses of the bushing design. I have been running the re-designed

bushing for a year in my printer without any more problems.

This listing is for 2 of the re-designed bushings, so you will have a

spare. It is made from a tough, abrasion and impact resistant urethane

and contains continuous strand carbon fiber tow running the full length

of the bushing. The tabs on either end of the bushing are much thicker

than stock, but the center area maintains the 2mm thickness of the stock

bushing, so print head height remains correct.

Included are photo illustrated instructions of an easy method (I've had

a lot of practice) of installing the bushing in a Z2100 printer, that

does not require the degree of dis-assembly suggested in the Service

Manual. It is still necessary to remove the cover over the right side of

the printer which requires a Torx 15 screwdriver, and in addition you

will need a small flat blade screwdriver and needle nose pliers or large

tweezers and a good light source.

The $15 price includes 2 rear carriage bushings, illustrated

installation instructions and free postage in the USA."

On Luminous-Landscape forum, a member, "Roscolo" discusses a replacement

procedure shortcut:

"First, you do this at your own risk. If you need

to install a new Rear Carriage Bushing, I think the odds of you screwing

something up are infinitely greater if you follow the instructions in

the z3100 Service Manual (take the whole printer apart) than doing what

I outline below (only remove the Right Cover), but, bottom line, they

tell you to do it their way. I think my way is better, but don't blame

me if you screw it up.

If you replace your belt on the HP z3100 / HP z3200 it is EASY to break

or lose the Rear Carriage Bushing. It is also VERY EASY to miss this

problem until AFTER you have replaced your belt and reassembled your

printer and find that it is dragging the heads or the carriage on your

paper/canvas, streaking/smearing ink, and making some loud banging

noises when the Carriage travels to the right. So when you replace your

belt, double and triple check that your Rear Carriage Bushing is on AND

that it isn't cracked (it is extraordinarily flimsy plastic) and you

won't have to do what I did.

BUT if you need to replace or install the Rear Carriage Bushing on the

z3100 / z3200, the manual tells you to essentially disassemble the

ENTIRE printer just like you have to do to replace the belt. YOU DO NOT

HAVE TO DO THIS (if you're careful.) Just remove the Right Cover. When

you pull the Carriage all the way to the right, (use a bright light

shining in there so you can see), you will see the hole where the far

end of the Bushing goes and the hole where the near part of the Bushing

goes (look at the diagram in the Service Manual). I just used a pair of

needle nose pliers to hold the bushing so I didn't lose it, (don't let

go!) and using a tiny 4 inch screwdriver (tiny like you could remove the

back of a watch with it), was able to gently force the far end of the

bushing into the far hole. Then CONTINUING TO HOLD ON TO THE BUSHING

WITH YOUR PLIERS, push or pull back that fleshy colored piece of rubber

thingy in the way, and you can easily apply tension to install the near

end of the bushing into the corresponding hole. If you bend the fleshy

rubber thingy a bit, use your pliers to bend it back like it was. This

saved me about 8 hours of headache NOT having to tear down and rebuild

the entire printer AGAIN, and eliminated the likelihood that I could

just as easily lose/break the bushing again when having to put the

Carriage back on!

I did this on the HP z3100. I have not done it on the z3200, but my

understanding is the printers are exactly the same in construction."

The rear carriage bushing also carries oil to lubricate the

carriage guide rod.

See diagram below:

The above illustration is for educational use and may be

subject to copyright

|

(These are my own

personal notes from repairs I have made.

I have made this web page for my own benefit, so I have a record of what

I have done.

If you use this information, do so at your own risk - I

assume no responsibility for errors.) |

|